Bowman’s Electric Turbo Compounding (ETC) technology was built on the long-established engineering principles of turbo compounding and turbocharging.

Whilst our patented system is unique in the power generation industry, turbo compounding itself has been in use for more than 70 years, including use in aircraft, motorsport engines, and heavy truck engines.

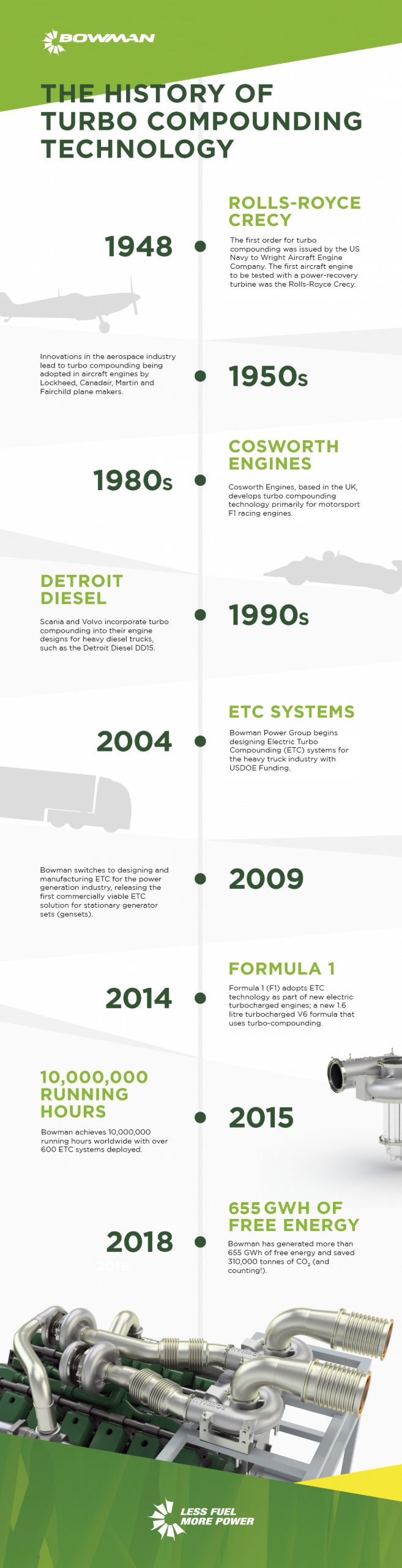

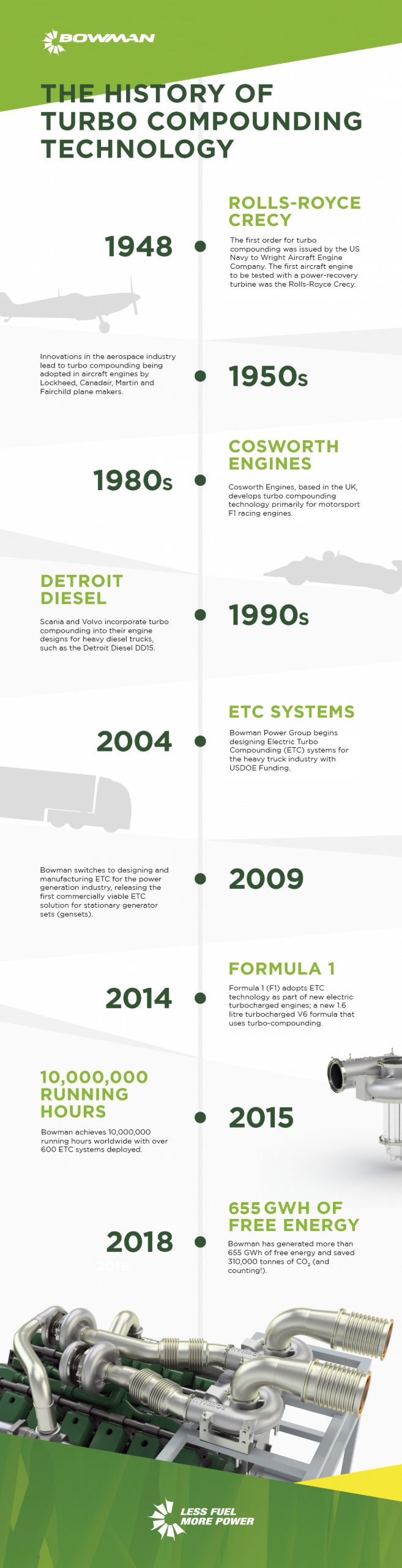

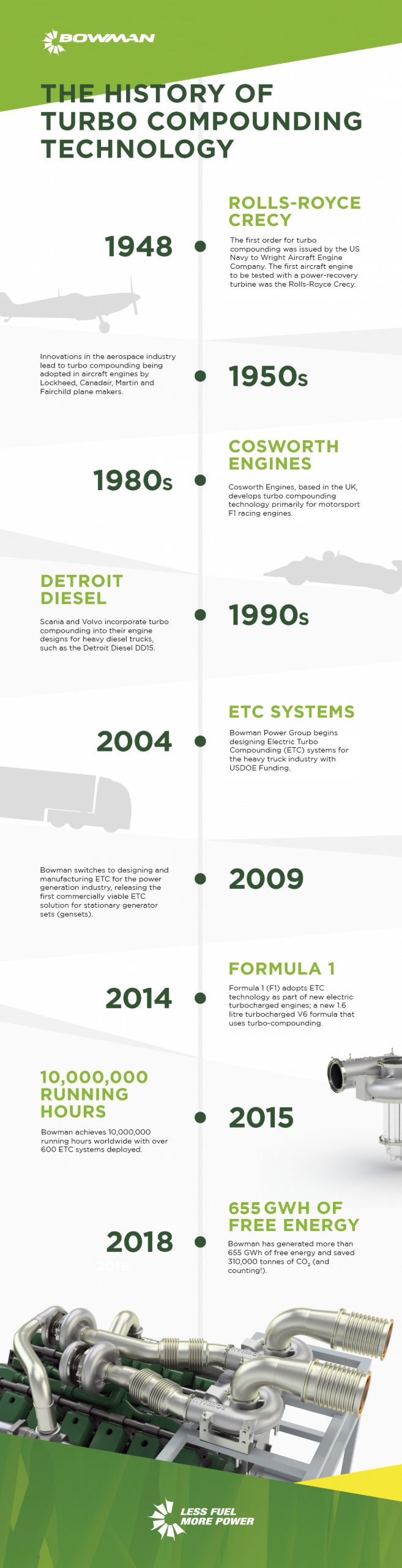

Turbo compounding; a visual history

Below, we have summarised some of the key developments in turbo compounding:

Turbo compounding; a brief history

- 1948: The first order for turbo compounding was issued by the US Navy to Wright Aircraft Engine Company. The first aircraft engine to be tested with a power-recovery turbine was the Rolls-Royce Crecy

- 1950s: Innovations in the aerospace industry lead to turbo compounding being adopted in aircraft engines by Lockheed, Canadair, Martin and Fairchild plane makers

- 1980s: Cosworth Engines, based in the UK, develops turbo compounding technology primarily for motorsport F1 racing engines

- 1990s: Scania and Volvo incorporate turbo compounding into their engine designs for heavy diesel trucks, such as the Detroit Diesel DD15

- 2004: Bowman begins designing Electric Turbo Compounding (ETC) systems for the heavy truck industry with USDOE Funding

- 2009: Bowman switches to designing and manufacturing ETC for the power generation industry, releasing the first commercially viable ETC solution for stationary generator sets (gensets)

- 2014: Formula 1 (F1) adopts ETC technology as part of new electric turbocharged engines; a new 1.6 litre turbocharged V6 formula that uses turbo compounding

- 2015: Bowman achieves 10,000,000 running hours worldwide with over 600 ETC systems deployed

- 2018: Bowman has generated more than 655 GWh of free energy and saved 310,000 tonnes of CO2 (and counting!).

The future of turbo compounding

With Bowman’s recent innovations in ETC technology for the power generation industry, as well as Formula 1’s adoption of the technology for motorsport, turbo compounding is seeing increased adoption for energy efficiency in a diverse range of environments. Now in its third generation, our ETC technology, the ETC 1000 represents the pinnacle of our 15 years of R&D with turbo compounding.

Bowman’s Electric Turbo Compounding (ETC) technology was built on the long-established engineering principles of turbo compounding and turbocharging.

Whilst our patented system is unique in the power generation industry, turbo compounding itself has been in use for more than 70 years, including use in aircraft, motorsport engines, and heavy truck engines.

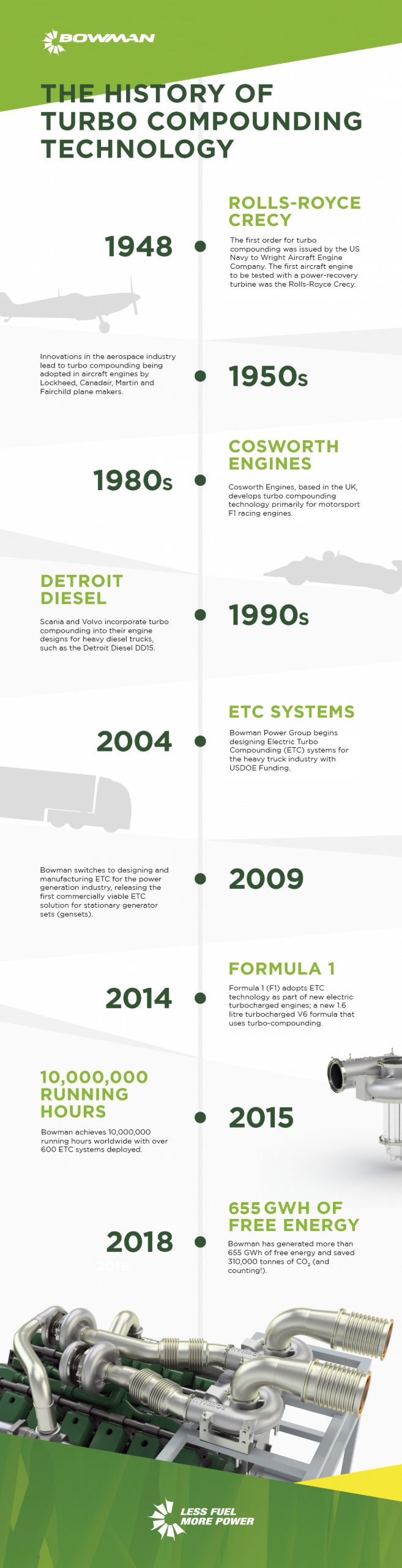

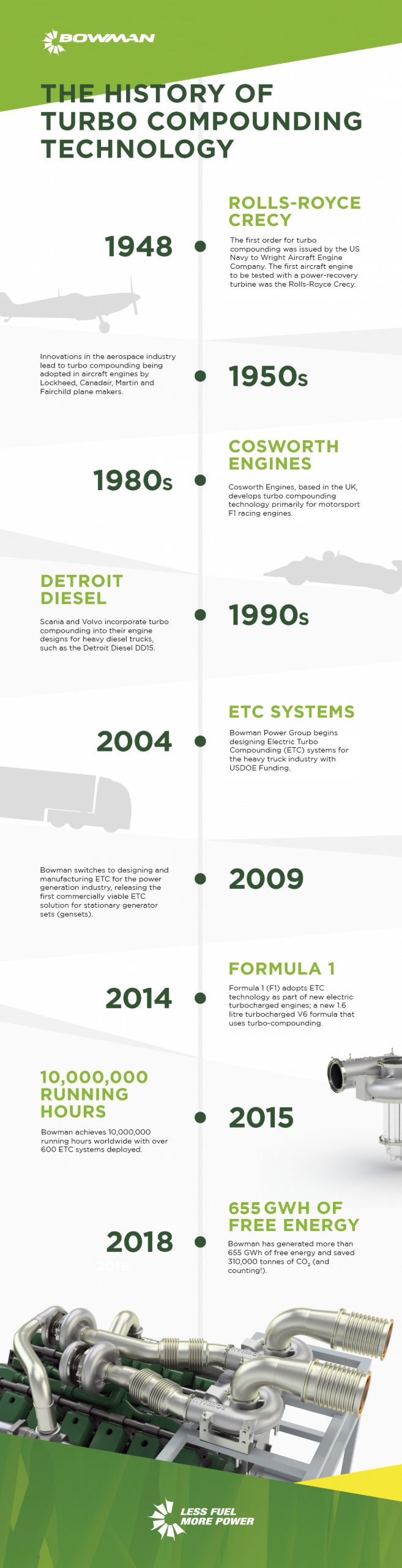

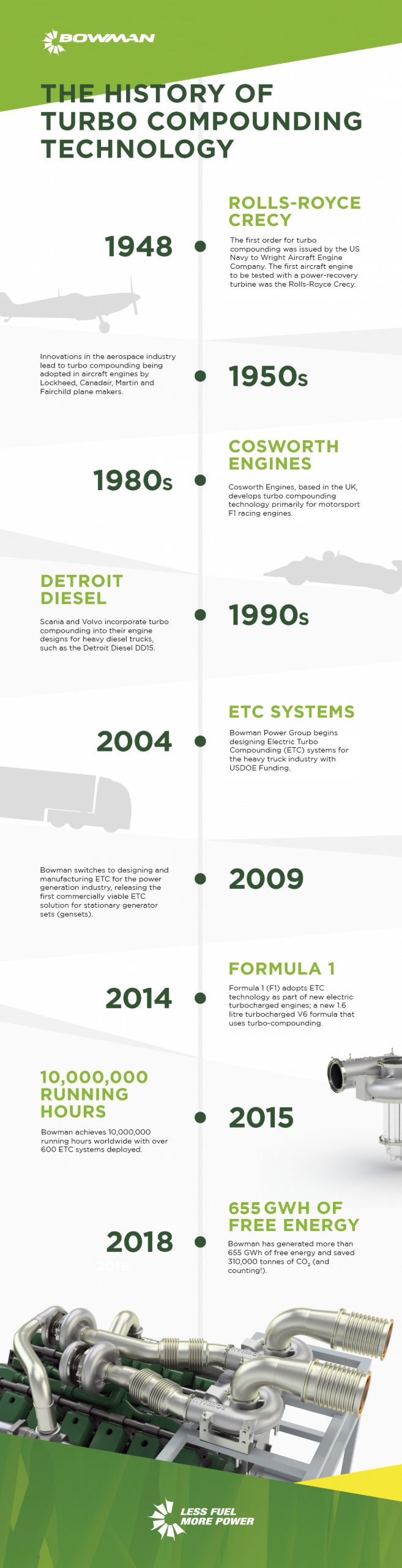

Turbo compounding; a visual history

Below, we have summarised some of the key developments in turbo compounding:

Turbo compounding; a brief history

- 1948: The first order for turbo compounding was issued by the US Navy to Wright Aircraft Engine Company. The first aircraft engine to be tested with a power-recovery turbine was the Rolls-Royce Crecy

- 1950s: Innovations in the aerospace industry lead to turbo compounding being adopted in aircraft engines by Lockheed, Canadair, Martin and Fairchild plane makers

- 1980s: Cosworth Engines, based in the UK, develops turbo compounding technology primarily for motorsport F1 racing engines

- 1990s: Scania and Volvo incorporate turbo compounding into their engine designs for heavy diesel trucks, such as the Detroit Diesel DD15

- 2004: Bowman begins designing Electric Turbo Compounding (ETC) systems for the heavy truck industry with USDOE Funding

- 2009: Bowman switches to designing and manufacturing ETC for the power generation industry, releasing the first commercially viable ETC solution for stationary generator sets (gensets)

- 2014: Formula 1 (F1) adopts ETC technology as part of new electric turbocharged engines; a new 1.6 litre turbocharged V6 formula that uses turbo compounding

- 2015: Bowman achieves 10,000,000 running hours worldwide with over 600 ETC systems deployed

- 2018: Bowman has generated more than 655 GWh of free energy and saved 310,000 tonnes of CO2 (and counting!).

The future of turbo compounding

With Bowman’s recent innovations in ETC technology for the power generation industry, as well as Formula 1’s adoption of the technology for motorsport, turbo compounding is seeing increased adoption for energy efficiency in a diverse range of environments. Now in its third generation, our ETC technology, the ETC 1000 represents the pinnacle of our 15 years of R&D with turbo compounding.

Bowman’s Electric Turbo Compounding (ETC) technology was built on the long-established engineering principles of turbo compounding and turbocharging.

Whilst our patented system is unique in the power generation industry, turbo compounding itself has been in use for more than 70 years, including use in aircraft, motorsport engines, and heavy truck engines.

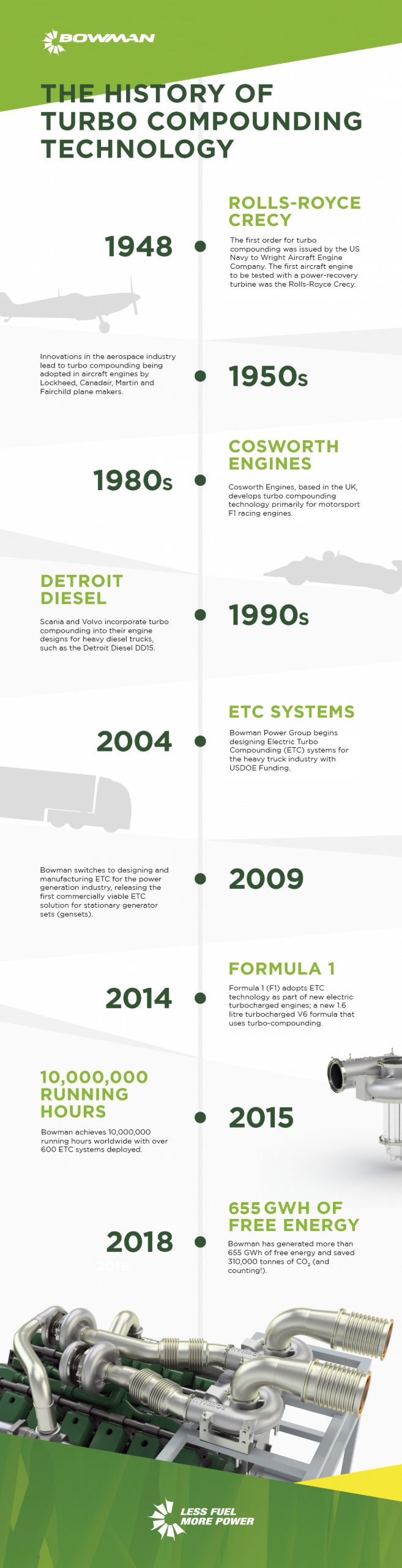

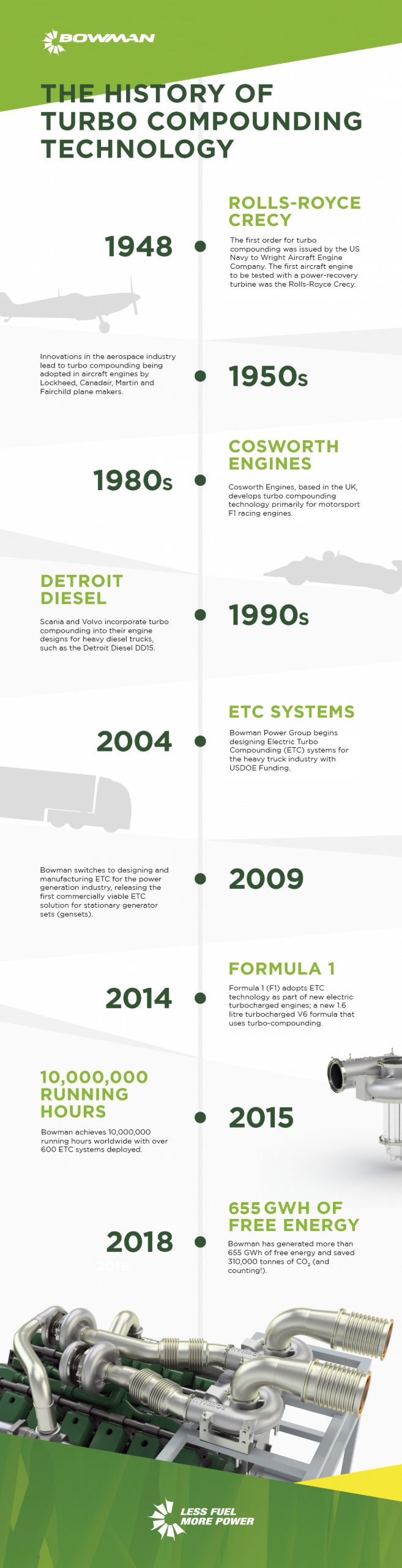

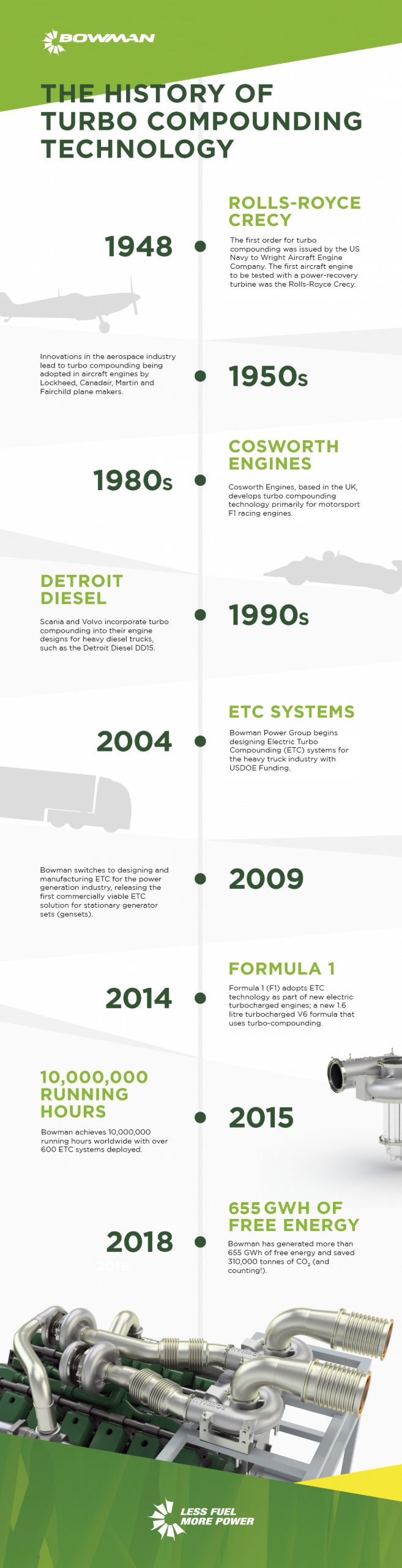

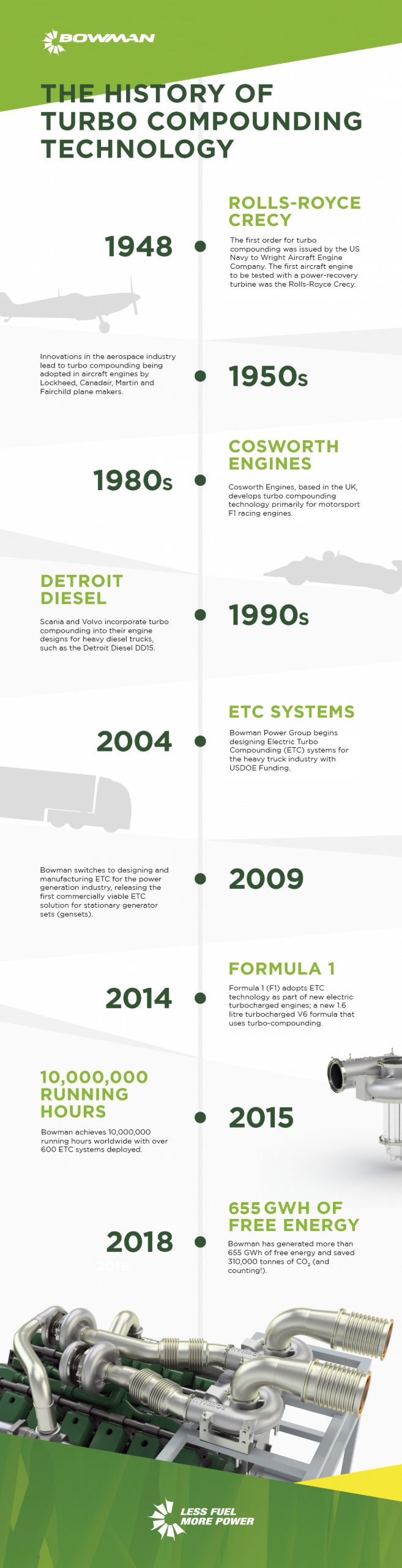

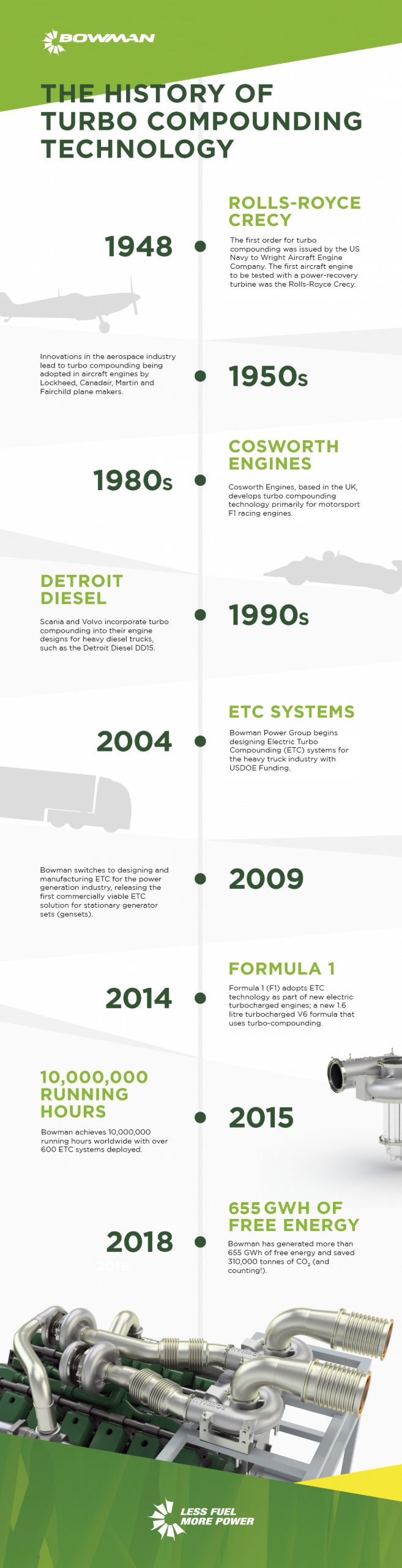

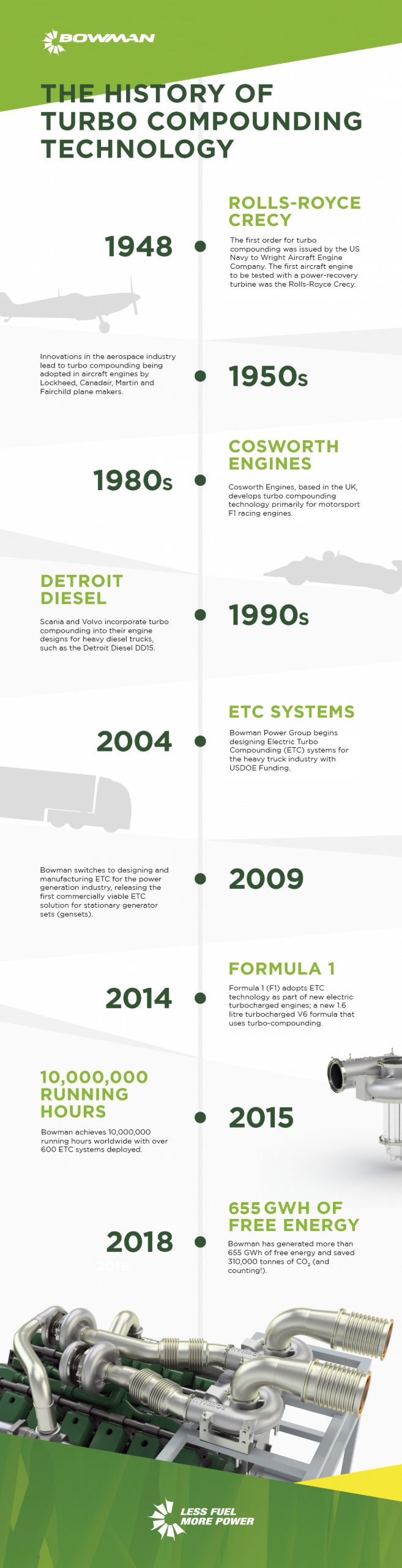

Turbo compounding; a visual history

Below, we have summarised some of the key developments in turbo compounding:

Turbo compounding; a brief history

- 1948: The first order for turbo compounding was issued by the US Navy to Wright Aircraft Engine Company. The first aircraft engine to be tested with a power-recovery turbine was the Rolls-Royce Crecy

- 1950s: Innovations in the aerospace industry lead to turbo compounding being adopted in aircraft engines by Lockheed, Canadair, Martin and Fairchild plane makers

- 1980s: Cosworth Engines, based in the UK, develops turbo compounding technology primarily for motorsport F1 racing engines

- 1990s: Scania and Volvo incorporate turbo compounding into their engine designs for heavy diesel trucks, such as the Detroit Diesel DD15

- 2004: Bowman begins designing Electric Turbo Compounding (ETC) systems for the heavy truck industry with USDOE Funding

- 2009: Bowman switches to designing and manufacturing ETC for the power generation industry, releasing the first commercially viable ETC solution for stationary generator sets (gensets)

- 2014: Formula 1 (F1) adopts ETC technology as part of new electric turbocharged engines; a new 1.6 litre turbocharged V6 formula that uses turbo compounding

- 2015: Bowman achieves 10,000,000 running hours worldwide with over 600 ETC systems deployed

- 2018: Bowman has generated more than 655 GWh of free energy and saved 310,000 tonnes of CO2 (and counting!).

The future of turbo compounding

With Bowman’s recent innovations in ETC technology for the power generation industry, as well as Formula 1’s adoption of the technology for motorsport, turbo compounding is seeing increased adoption for energy efficiency in a diverse range of environments. Now in its third generation, our ETC technology, the ETC 1000 represents the pinnacle of our 15 years of R&D with turbo compounding.